Bright minds delivering innovative solutions for underwater operations

At Subsea Formula, we are a cohesive team of experts in robotics, electronics, mechanical engineering, mathematics, chemistry, and software development, dedicated to providing state‑of‑the‑art tools for underwater operations.

We offer a personal, considered approach, applying rigorous thinking to find the best solution. Communication is direct with senior experts who plan, oversee and deliver the work, rather than through a soulless, process-led handover.

Subsea Formula has its own facilities and equipment for the manufacture of high‑quality components and tools, and our team also has strong relationships and an extensive network across German manufacturing facilities, forged over years of collaboration.

Robotics innovator and deep-tech visionary with 30+ years’ experience across robots, medical devices, FES, enterprise software, and integrated platforms (auto anti-theft, GLONASS/GPS). MS in Applied Mechanics; known for unconventional solutions.

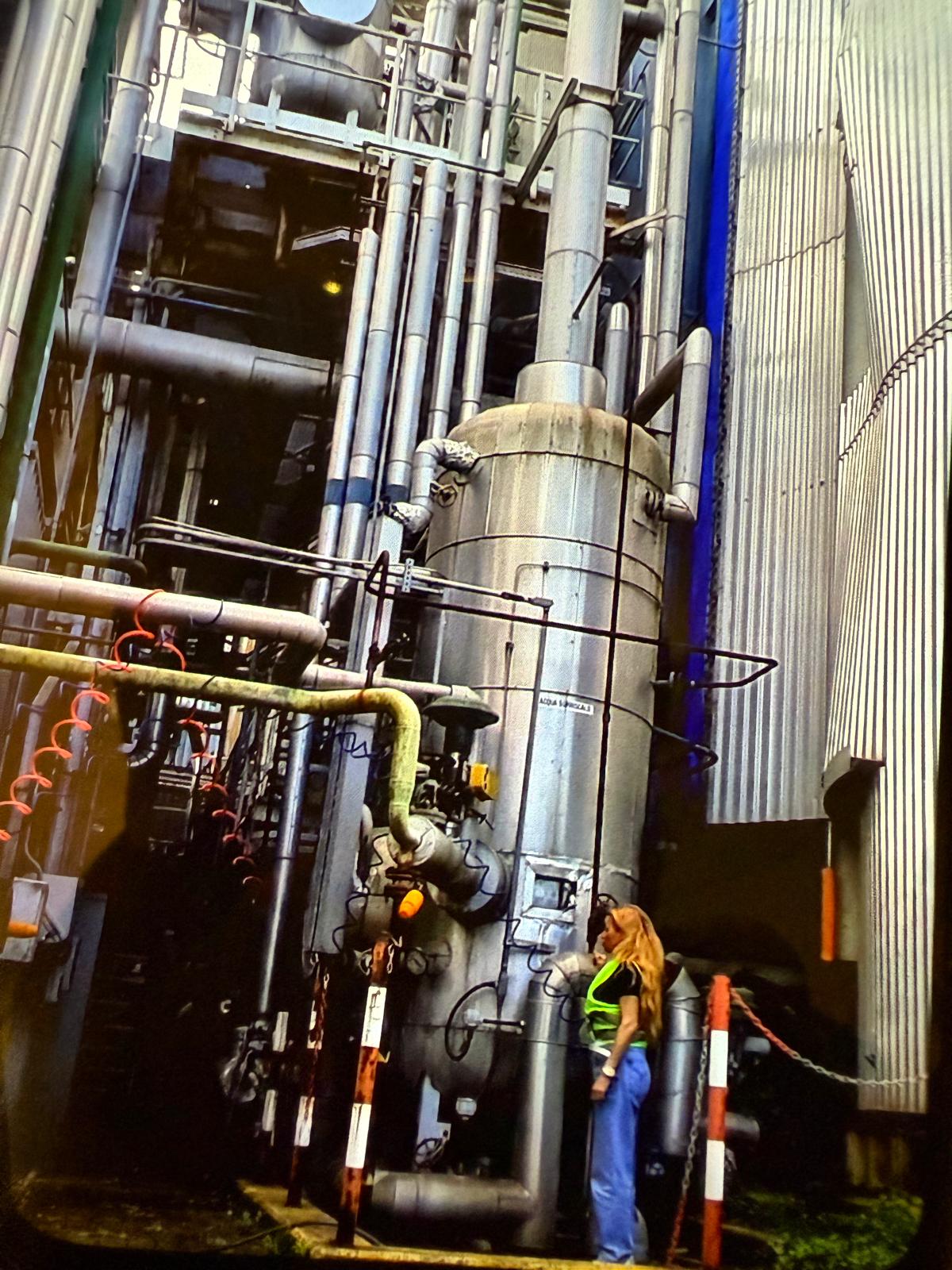

Julia has extensive experience in the industrial sector. She has served as an official distributor for Terranova and Spriano, focusing on measurement equipment and automation solutions for the maritime and industrial sectors.

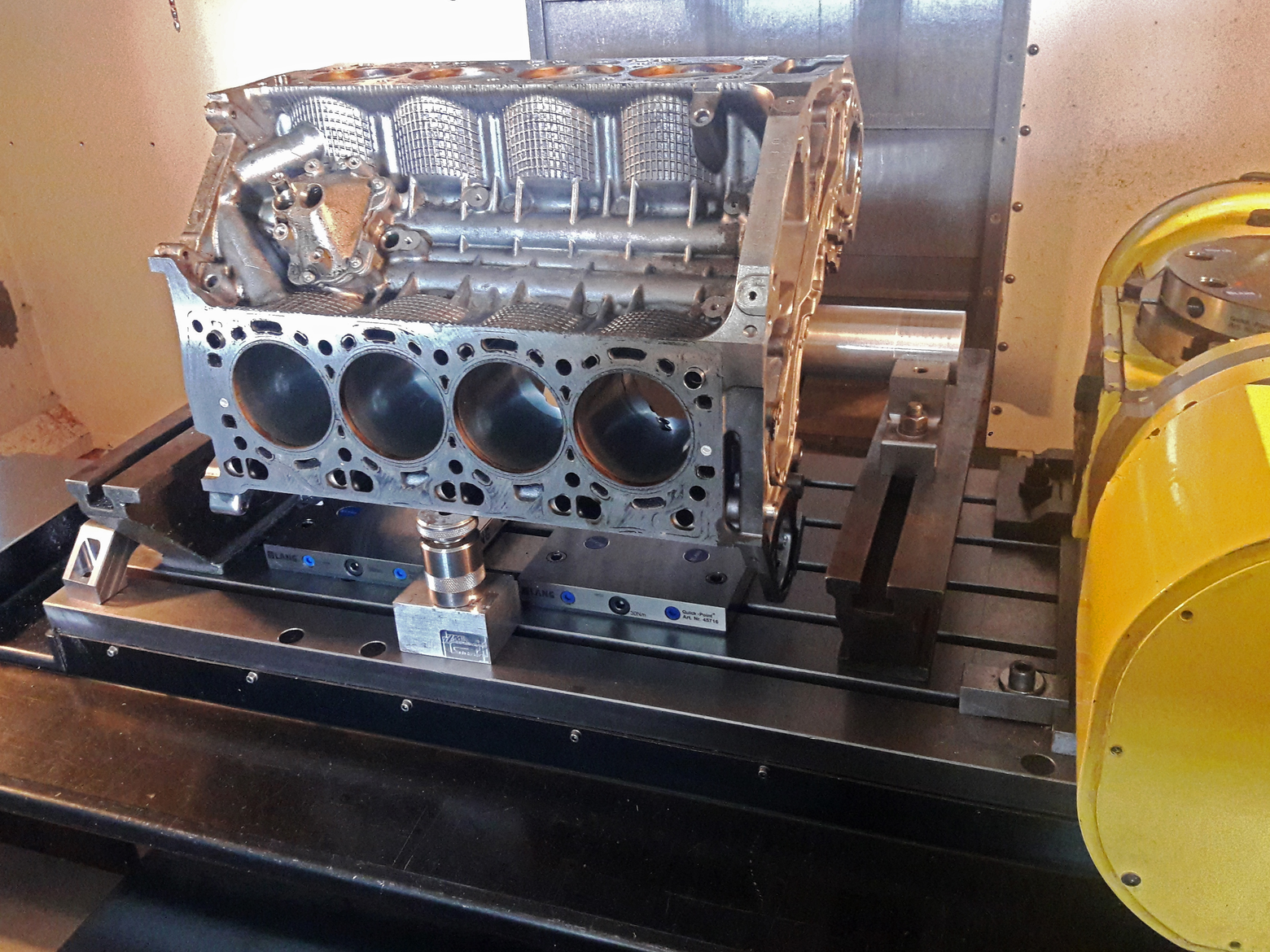

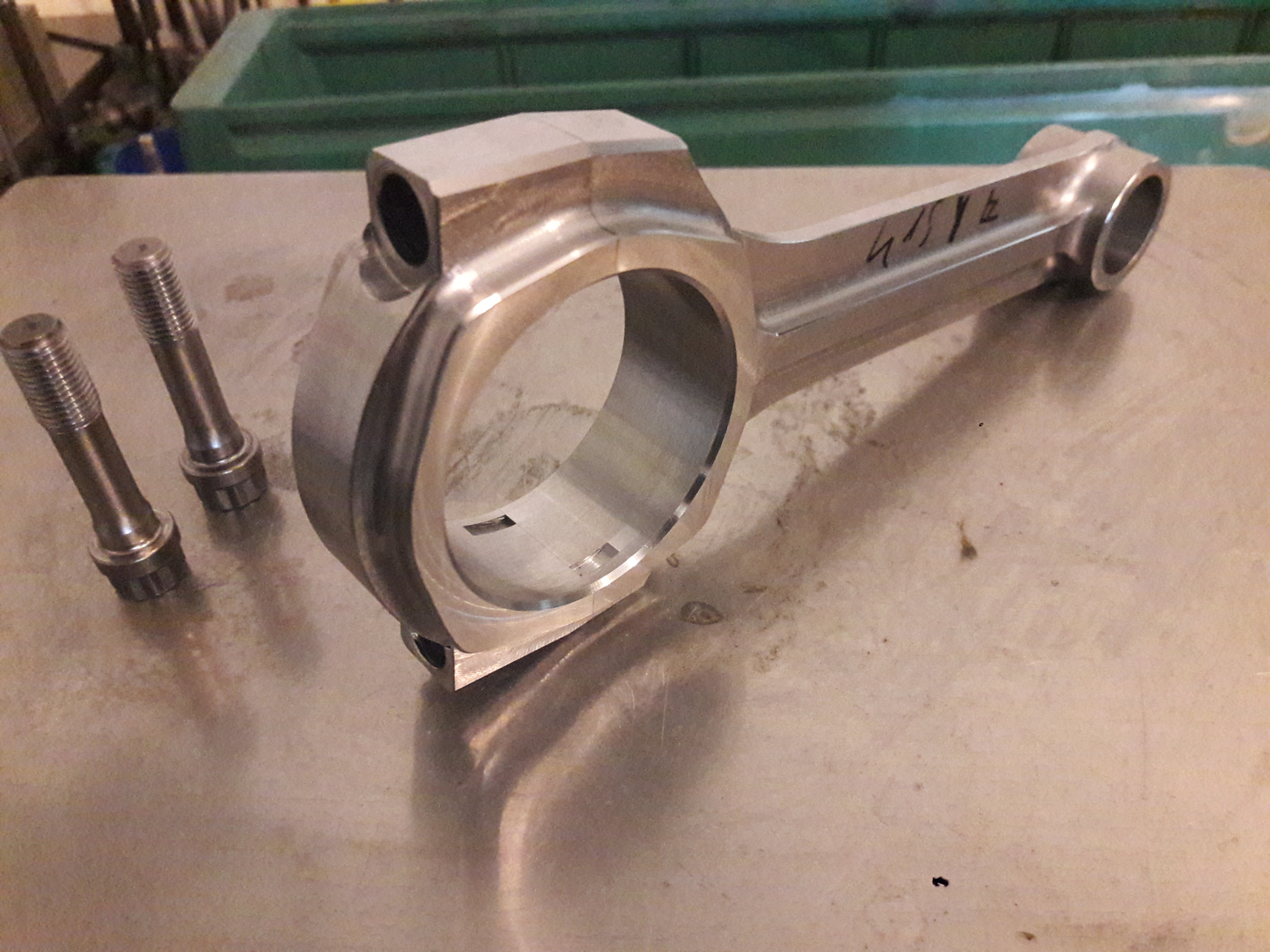

Robert has extensive experience in CNC machining and manufacturing advanced components for complex requirements, including those for racing car teams and subsea tools.

Specialist in applied mathematics and mechanics, mathematical modelling, computational problem-solving, and software and hardware testing. She possesses exceptional organisational skills.

Dmitry holds expertise in software and AI engineering, as well as mechatronics and electronics engineering. He is a young, versatile, skilled, and hard-working professional.

An extensive network of experts in science, physics, chemistry, and mathematics for cutting-edge research, along with partners equipped with the tools and expertise required for high-precision component manufacturing.

Vera can find beauty anywhere and she always shares it with others. A master of photography and visual storytelling, she transforms moments into stories rich in atmosphere and emotion.

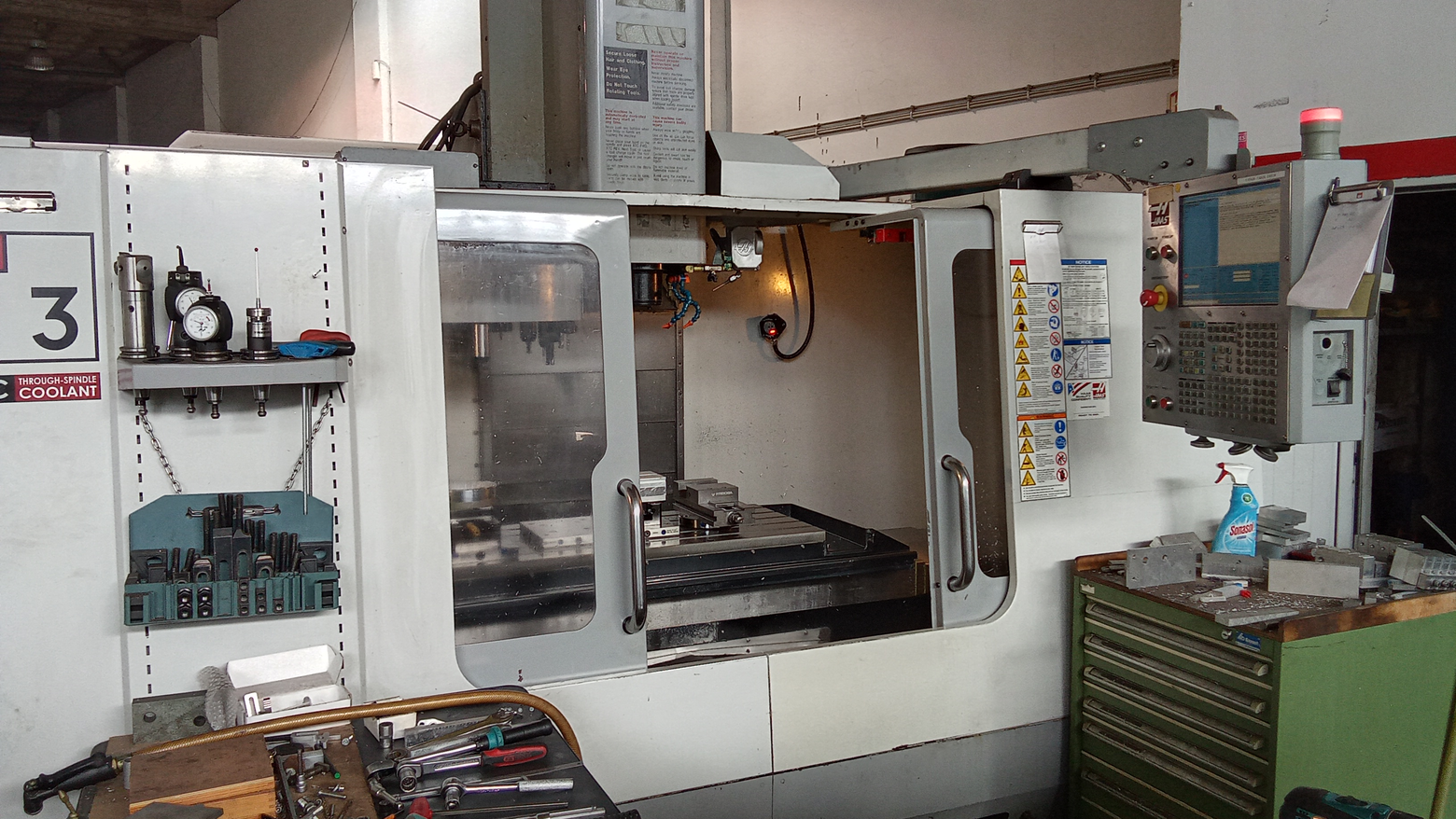

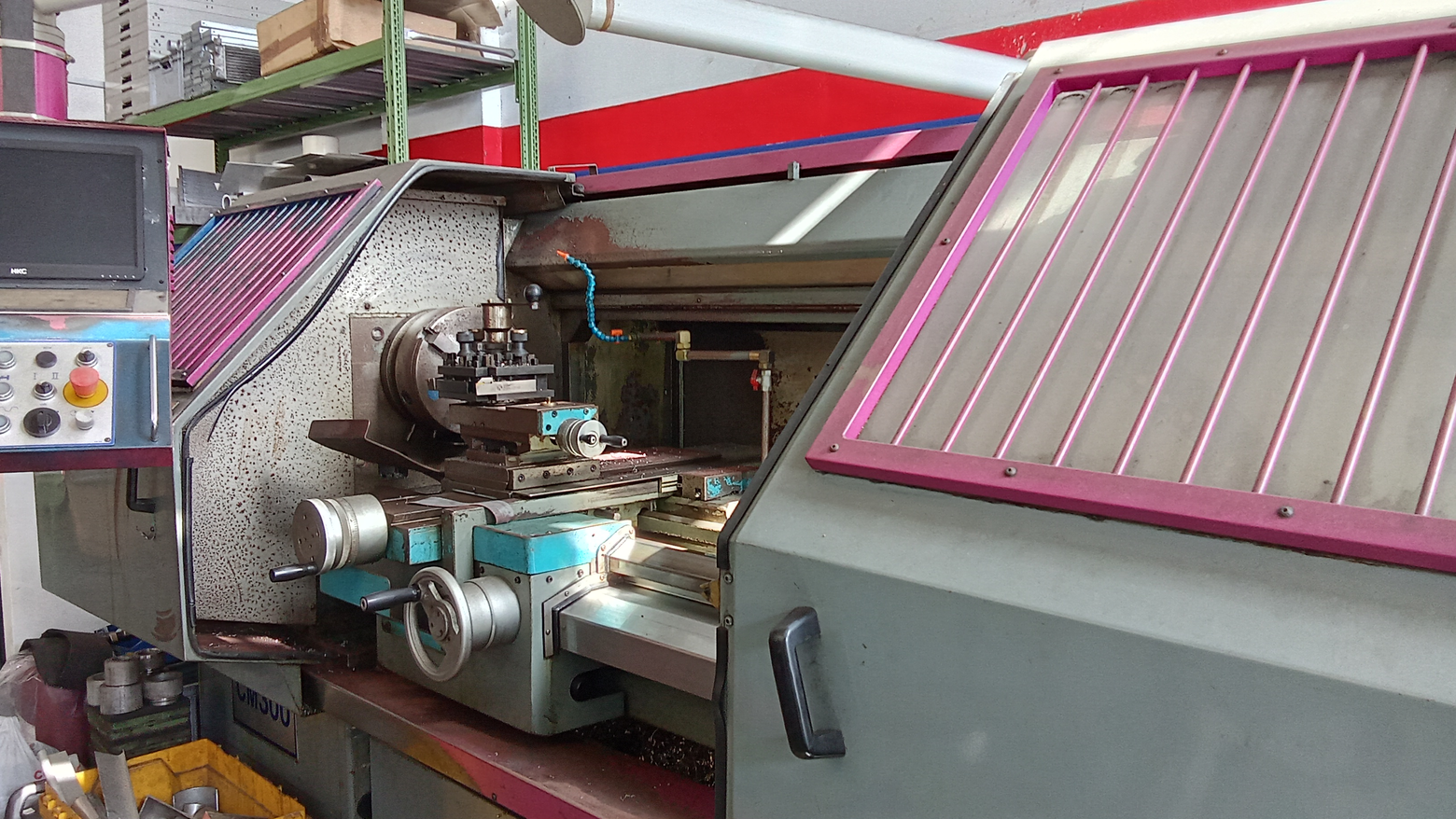

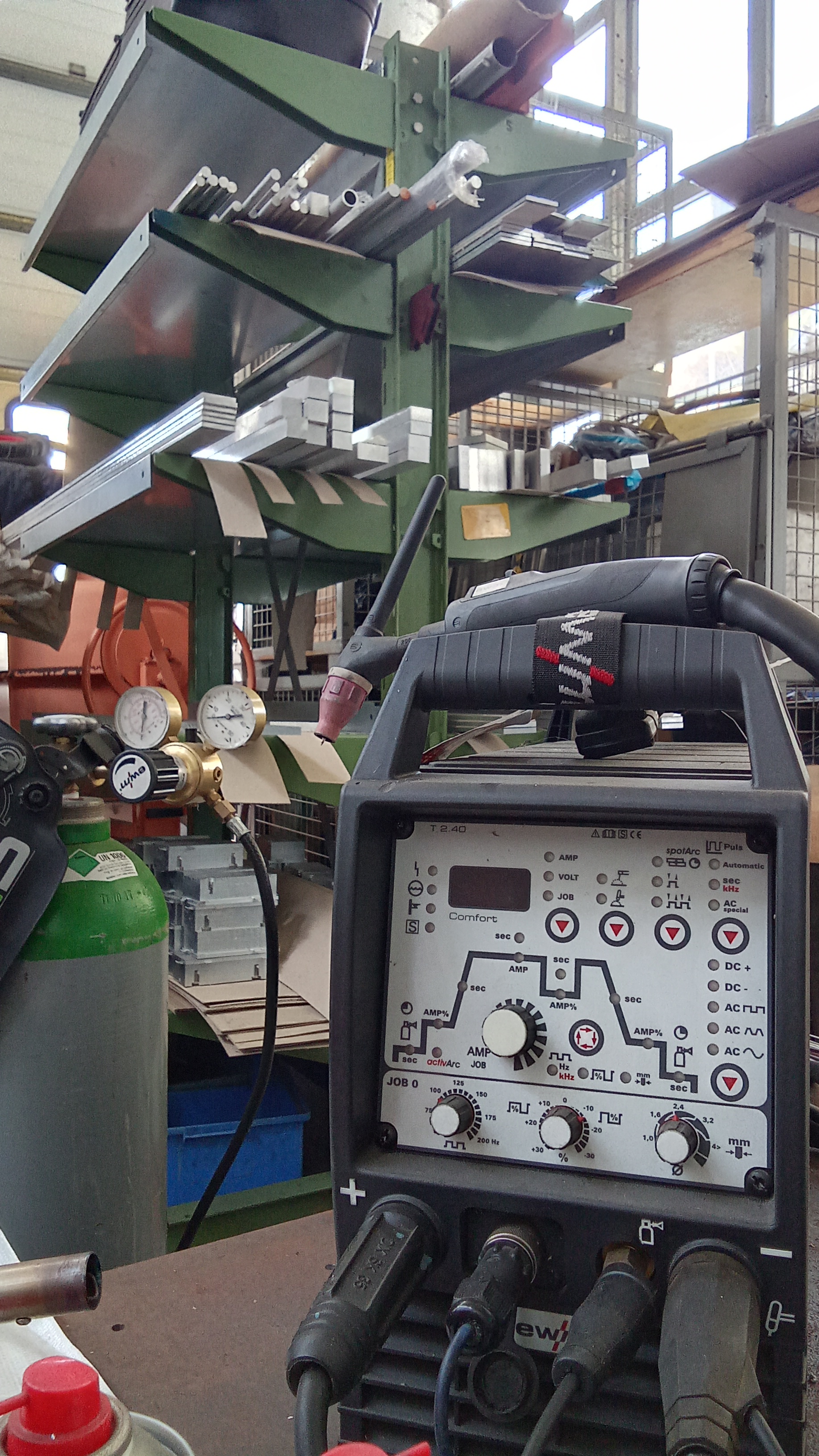

A wide range of machinery and tools is available on site including 3‑axis CNC milling machine, lathes, grinding and drilling machines, CNC plasma cutting system, welding systems, press, tube and pipe benders, guillotine, hyperbaric pressure test chambers, ultrasonic testing equipment and a lot of accompanying tools together with other equipment for thorough flaw detection.

We work with 316/316L stainless steel, titanium grades 2 and 5, nickel‑based alloys, nickel aluminium bronze, and aluminium, selected according to the requirements of each project. Equipment and materials are applied accordingly throughout manufacture and testing.

We have everything needed to manufacture high‑quality ROV parts and tools.

3‑axis CNC milling machine

Lathe for long and/or large-diameter workpieces, standard turning lathe

Bandsaw, press, welding machine

Guillotine, tube and pipe benders, CNC plasma cutting system

Subsea Formula team is distributed across London, Istanbul and Funchal, Madeira.

Our R&D team and facilities are based in the picturesque city of Funchal on Madeira Island. We are ideally situated to test and develop subsea products in a real‑world environment. Madeira, the summit of a massive volcano rising 6 km from the Atlantic Ocean floor, offers rapidly deepening waters perfect for rigorous product testing.

Kirill’s track record spans practical robotics, sensing, energy, and medical engineering, with a bias for building rigorously and shipping fast.

RoboArm, a three‑metre, 350 kg teleoperated hand, let children mirror finger motions via a glove and became a showstopper for Volkswagen dealers, Volvo’s heavy machinery division, and major events—ultimately evolving into a commercial attraction.

Mad Chair, a battery‑electric tracked chair for slopes, sand, and shallow water, paired strong low‑speed torque with clutch protection and a joystick controller, proving a robust, crowd‑friendly ride at public activations.

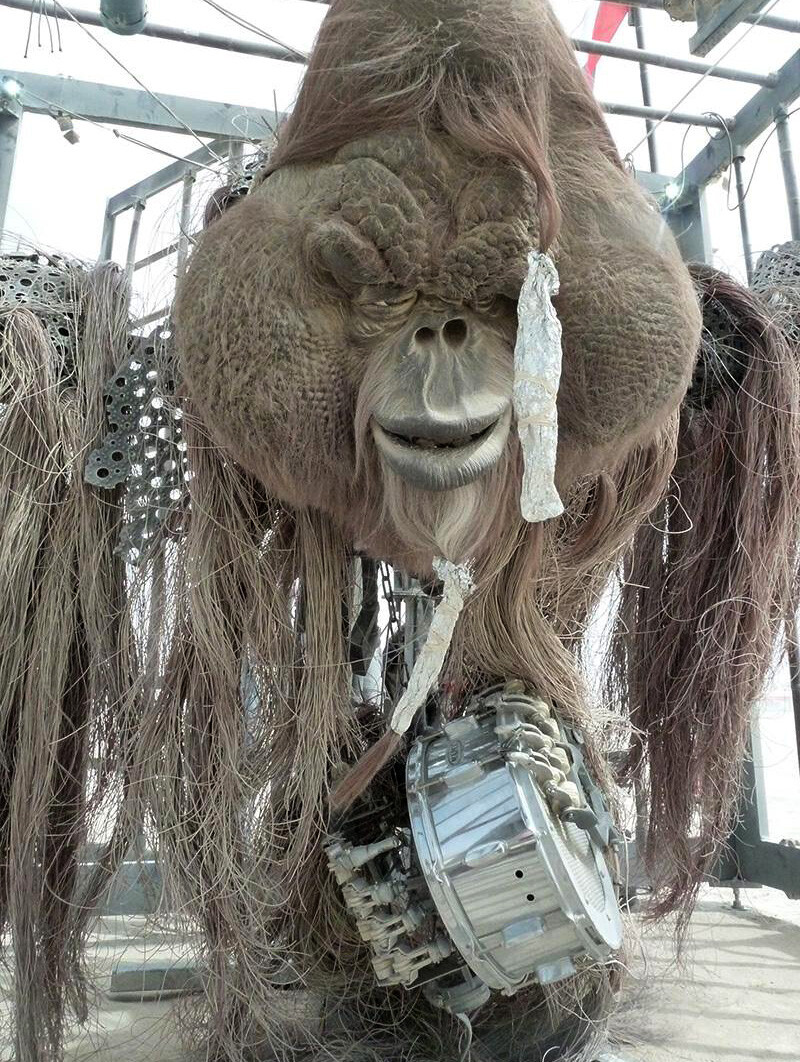

OraculeTang, a speaking animatronic orangutan built in eight weeks—ran reliably in Black Rock Desert’s corrosive dust at Burning Man 2015, while Alien Egg, a flyable ovoid stage prop, used a steel frame, fibreglass shell, aluminium manipulators, and compact adjustable clutches so a performer could shape kaleidoscopic mirror effects and hold them precisely during a safe, repeatable lift.

In energy, a palm‑sized flywheel prototype demonstrated spin‑up and power return with available materials and electronics, earning a gold medal at the Archimedes innovation fair before being paused pending scale‑up investment and a clear route to market. In navigation, a multi‑channel, multi‑constellation GNSS receiver progressed from bench builds to a custom baseband processor, with a host‑side interface exposing live channel and signal diagnostics.

Spaceflight training work includes an orbital docking simulator for the Gagarin Cosmonaut Training Center, combining real‑time dynamics, 3D visuals, virtual instruments, and centrifuge integration to reproduce g‑loads for manual approach practice.

In healthcare, the Medical Nanofilter Plant defined an automated line to make low‑cost respiratory filters that preserve humidity, block microbes, and partially scrub CO₂—an approach positively assessed in a naval medical setting—while a clinic‑commissioned, mammography‑guided sampling probe delivered a complete device architecture and operator test interface.

This breadth—teleoperation, power and control, harsh‑environment reliability, and human‑centred interfaces—underpins how our team now designs, powers, and safeguards underwater systems.

Robert has over 23 years of experience in machining and engine engineering. His early work focused on engine parts for racing engines, followed by producing components for specialist applications such as aerodynamic parts for drones and wings for wind farms.

Robert has developed:

Robert has hands-on experience programming engine control units (ECUs), including wiring harnesses and full engine builds. Notably, he also has experience with alcohol‑fuelled engines.

Robert demonstrates high proficiency in CNC machining, able to construct and mill complex parts. He has extensive experience working with Grade 5 titanium, noted as a particularly challenging yet strong material. He is proficient in machining stainless steel, nickel alloys, bronze and other common CNC materials, though titanium remains the standout due to its difficulty and mechanical properties. He is skilled in TIG welding of stainless steel (inox), aluminium and steel, and performing post‑weld machining.

Over his career, has implemented complex projects from initial design and calculations through prototyping to small‑batch production. He is capable of performing finite element analysis (FEA) and preparing full documentation. Robert enjoys seeing a designed part materialise and function, whether it moves or remains static, and relishes problem‑solving throughout the project lifecycle.

Julia led the preparation and sale of a 150 MW gas-fired power plant, overseeing documentation management and stakeholder relationships. Also Julia has a proven and distinguished record in yacht sales.

We warmly welcome clients to visit and experience the natural beauty of Madeira, with its comfortable climate, clean sea air, and stunning views of the mountains and the open ocean. Many choose to extend their stay, and we are delighted to organise personalised tours to showcase the island’s hidden gems, far from the typical tourist paths.

Explore the future of subsea technology with us in one of the world’s most beautiful and dynamic testing grounds.