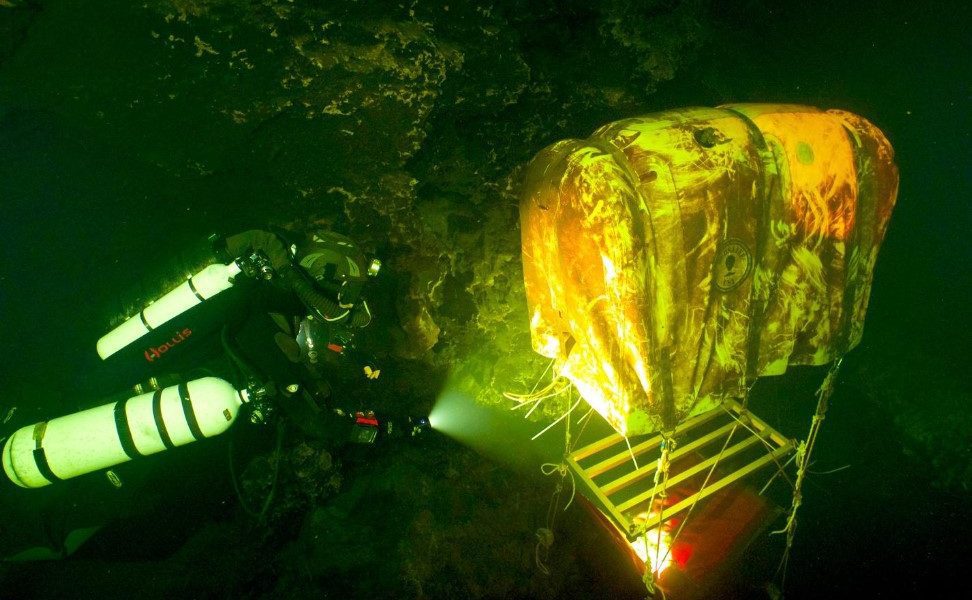

Air lift bags are widely used in the maritime industry, with their main advantages being cost-effectiveness and compact size when folded. Light salvage bags weighing 50–500 kg cost $130–$800, and from to $5,000+ for industrial systems, making them the most economical lifting solution available. These systems are operated by divers rather than ROVs in shallow water environments, reducing operational complexity and equipment requirements.

Key Advantages

The lowest price point compared to alternative lifting methods makes lift bags accessible for various marine operations. Their compact storage requirements allow easy transport and deployment from smaller vessels, while variable load capacities ranging from 50 kg to over 100,000 kg provide customizable configurations using modular systems. This well-tested and widely adopted technology has become routine for salvage operations down to depths of approximately 50 meters, with established protocols ensuring reliable performance.

Operational Limitations

Operations are primarily limited to depths of 50 meters where pressure changes remain manageable for safe ascent control. Over-inflation or valve failure can cause rapid ascents, though modern systems now incorporate sophisticated management protocols to mitigate these risks through automated dump valves and pressure monitoring systems.

For lifting up to 1,500 kg from depths exceeding 300 meters without divers, consider the NetGrappler solution, which provides ROV-assisted cargo retrieval capabilities

Safety Standards

Industry standards such as IMCA D-016 mandate a 6:1 safety factor, meaning a bag rated for 10,000 kg possesses a breaking strength of 60,000 kg. Operational limits typically apply a 20–30% buffer below rated capacity to account for dynamic forces during lifting operations, ensuring safe margins under varying conditions.

Staged Lift Protocols

- During the breakout phase, initial bags such as 20-ton units overcome embedment forces while subsequent bags provide incremental lift capacity, allowing teams to gradually free objects from seabed adhesion without sudden movements that could damage cargo or equipment

- Ascent control operations involve surface teams monitoring air release through umbilical-fed valves, maintaining precise ascent rates below 0.5 m/s to prevent uncontrolled rising that could lead to equipment failure or cargo damage during the critical lifting phase

- Surface transfer procedures utilize marker buoys and support boats to guide recovered cargo safely to deck areas, coordinating multiple vessels and personnel to ensure smooth transition from underwater recovery to surface handling and final positioning

Air Lift Bags Applications

Marine Engineering and Construction - Lift bags serve as essential tools for positioning and installing heavy underwater infrastructure such as pipelines, platforms, and subsea components. Engineers can precisely control buoyancy to maneuver large structures during construction, reducing installation risks and enabling accurate placement in challenging underwater environments. The bags facilitate both new construction projects and maintenance of existing underwater installations.

Salvage Operations - The recovery of sunken vessels represents the most prominent application for lift bags, ranging from small recreational boats to large commercial ships. Salvage teams strategically attach multiple bags to provide controlled buoyancy, enabling the raising of heavy objects from the seabed while minimizing structural damage during ascent.

Archaeological and Cultural Heritage Recovery - Underwater archaeologists utilize lift bags to carefully retrieve artifacts and historical objects from shipwrecks and submerged sites. The precise buoyancy control allows for delicate handling of fragile items while avoiding damage to surrounding archaeological contexts and enabling systematic recovery operations.

Military and Explosive Ordnance Disposal - Military applications include mine clearance operations and recovery of underwater ordnance. Specialized lift bags with remote control capabilities enable safe retrieval of explosive devices without direct human contact, while also supporting recovery of military equipment and vehicles from underwater environments.

Emergency Response and Firefighting - Fire departments and rescue teams deploy lift bags for vehicle extrication and structural collapse scenarios. The bags can lift heavy vehicles trapping victims or create void spaces in rubble, providing rapid response capabilities in time-critical emergency situations.

Environmental Cleanup Operations - Environmental recovery projects utilize lift bags to remove debris, pollutants, and hazardous materials from underwater sites. This includes cleanup of industrial waste, removal of sunken equipment, and restoration of contaminated aquatic environments while minimizing ecological disturbance.

Law Enforcement and Forensic Investigations - Police and investigative teams employ lift bags for evidence recovery, including retrieval of weapons, vehicles, and other items from underwater crime scenes. The controlled lifting process helps preserve chain of custody and maintains the integrity of forensic evidence.

Commercial Diving Operations - Professional diving companies use lift bags across various commercial projects, from offshore oil and gas operations to underwater welding and maintenance tasks. The bags provide versatile lifting solutions for routine maintenance and installation work in marine industrial settings.

Marine Research and Exploration - Scientific research operations rely on lift bags to retrieve instruments, samples, and specimens from the ocean floor. Marine biologists, geologists, and oceanographers use these tools to recover sensitive research equipment and biological samples while ensuring minimal impact on delicate underwater ecosystems.

Equipment Recovery - Military and industrial equipment retrieval from firefighting wells, training sites, and operational environments. Specialized operations involve recovering heavy military equipment using closed-bottom bags that prevent silt intrusion during lifting operations with rapid deployment capabilities.

Vehicle Extrication - Fire department operations using low-pressure lift bags to free victims trapped under vehicles. Emergency responders utilize specialized bags designed for rapid deployment and controlled lifting, with integrated stabilization systems preventing secondary collapse during rescue operations.

Structural Collapse Rescue - Creating void spaces in rubble using collapsible hydraulic lift bags in emergency rescue scenarios. Rescue teams deploy bags with minimal insertion heights to access confined spaces within collapsed structures, utilizing reinforced fabrics to resist punctures from debris.

Coral Reef Restoration - Repositioning dislodged coral colonies using foam-filled bags that minimize disturbance to sensitive marine habitats. Marine biologists utilize static-buoyancy foam bags to eliminate venting risks that could disturb sediment and damage surrounding coral polyps during restoration operations.

Oil Spill Response - Containing submerged hazardous materials using chemically resistant lift bags for controlled environmental cleanup. Environmental response teams deploy bags with specialized PVC liners to contain leaking fuel and hazardous materials during controlled ascent to surface containment systems.

Case Studies - Real-World Lift Bag Operations

Port of Salalah Cyclone Recovery (2018)

Following Cyclone Mekunu’s devastating impact, Unique Group deployed 28×10-ton and 8×20-ton Seaflex Air Lift Bags to clear storm wreckage from Salalah’s port. Divers secured bags beneath cargo dhows, shipping containers, and helicopter platform sections using single-point attachment systems with staged inflation protocols. The vessel Jawar Abu Dhabi coordinated surface operations, successfully clearing critical shipping channels and restoring port functionality within the project timeline.

U.S. Gulf Coast Barge Salvage

A grounded barge recovery operation utilized open-bottom Seaflex™ Air Lift Bags in shallow-water environments where traditional crane access was impossible due to shoreline restrictions. Divers secured multiple bags beneath the hull using heavy-duty webbing and spreader bars, executing carefully sequenced lifts that overcame silt suction forces. Surface teams controlled inflation through umbilical-fed air supplies with inline valves maintaining precise ascent control while minimizing environmental sediment disturbance.

Northern Europe Quay Wall Container Recovery

Salvage teams recovered shipping containers trapped beneath a collapsed quay wall structure using modular air lift arrays in confined underwater spaces. Divers worked in restricted areas under partially submerged concrete structures, deploying multiple enclosed pontoons in sequential arrangements to prevent foundation destabilization. Each container required individual assessment and rigging with multiple bags per unit, while surface engineers monitored structural stability throughout the operation.

Miller & Carter Restaurant Salvage (2022)

MMC Diving Services recovered a 750-tonne replica paddle steamer restaurant that sank at Lakeside Shopping Centre using coordinated high-capacity lift bag systems. Operations in the confined shopping centre lake required careful coordination with facility management while working within a compressed three-day timeline. Teams assessed the structure’s underwater condition to determine optimal attachment points that preserved the restaurant’s historical replica features during surface transfer.

Equipment Failure Analysis - 3-Tonne Lift Bag Incident (2016)

Stainless steel lifting links failed catastrophically during saturation diving operations when bags broke away from pipeline connections, failing at 10 kN rather than the certified 18-tonne capacity. Post-incident metallurgical investigation revealed counterfeit certification with manufacturing defects where rings were improperly bent and welded during production. The incident led to enhanced industry procurement protocols and highlighted the critical importance of independent equipment verification in marine salvage operations.

In a nutshell, lift bags help marine salvage through adaptability and cost savings, though their success hinges on meticulous planning and risk mitigation.

They are not suitable for larger depths where robotic solutins thrive.